Acu-Res® Solid-state vs. Mechanical Wind Sensors:

February 27, 2025

Overview and background

In competitive yacht racing, real-time wind data is crucial for performance, strategy, and safety. The rise of hydro-foiling in the IMOCA class has resulted in faster yachts—reaching speeds up to 40 knots in IMOCA races—that are subjected to much higher slamming forces. Teams are finding that traditional mechanical wind sensors are failing under such extreme conditions. This has driven the industry to seek more durable and reliable alternatives.

This case study compares the performance of FT Acu-Res® solid-state wind sensors with mechanical counterparts in real-world racing conditions. As Time-of-Flight (ToF) ultrasonic wind sensors rely on precise timing of ultrasonic pulses, they can face reliability challenges, particularly in extreme conditions.

In contrast, FT wind sensors use an acoustic resonance principle (Acu-Res®), amplifying sound waves within a resonant chamber. This measurement principle eliminates the need for timing calculations, making Acu-Res® technology more accurate, robust, and resistant to environmental interference.

Real World Comparison

The VandB team, led by skipper Maxime Sorel, tested two different wind sensors under varying conditions—including light breezes, strong winds, and stormy weather. An FT Technologies Acu-Res® wind sensor, was mounted horizontally on the masthead and a traditional mechanical wind sensor, mounted vertically on the masthead.

This setup provided a direct, real-world comparison of performance under extreme conditions, capturing over 63 hours of continuous yacht race data which they generously shared with us.

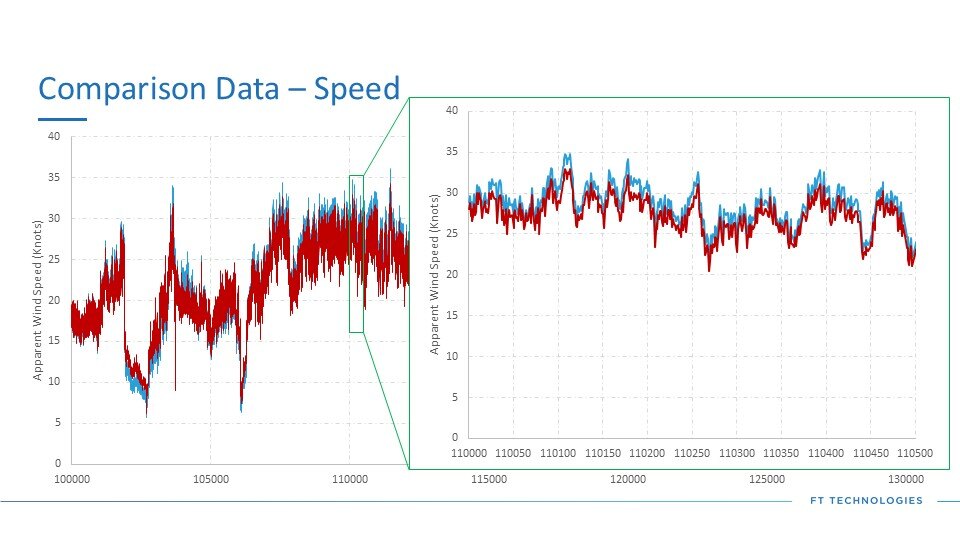

As shown in the comparison data charts, both the FT wind sensor (blue) and the mechanical wind sensor (red) demonstrate consistent and reliable wind speed and direction measurements.

Results & Comparison

Accuracy & Responsiveness: Just like traditional wind sensors, the FT wind sensor demonstrated consistent high performance seen at the masthead of the IMOCA yacht.

Durability & Maintenance: The improved reliability of non-moving parts in a solid-state FT wind sensor provided peace of mind in high-impact conditions with very little wear and tear over time. Mechanical sensors risk breakage under prolonged high-impact conditions.

Extreme Conditions Performance: The FT wind sensor remained unaffected by salt, water spray and vibrations from the boat. The built-in EMC/EMI protection ensured reliable performance, even in storm conditions and during lightning exposure.

Seamless Integration & Usability: FT wind sensors are compatible with existing onboard sailing systems, allowing the system to switch between mechanical and ultrasonic wind sensors. Data output and real-time usability are crucial in single-manned racing classes where autopilot control is a necessity.

Conclusion

After their rigorous testing, Maxime Sorel’s team chose to rely exclusively on FT wind sensors for the Vendée Globe in 2024/2025. With FT's Acu-Res® Technology, they provide accuracy and responsiveness, durability, and extreme conditions reliability in high-performance sailing.

For professional racing teams, the FT Acu-Res® wind sensors offer a clear advantage over traditional mechanical options, ensuring reliable wind data in the most extreme conditions.

Presentation

This case study is based on a presentation by Dr. Phil Richardson of FT Technologies at the Design & Technology Symposium during the Yacht Racing Forum 2024. His talk, titled "Can We Trust the Data? – Mechanical vs. Solid-State Wind Instruments in Offshore Racing," took place on November 20, 2024.

Join us for the next edition of METS Trade and Yacht Racing Forum at the RAI Amsterdam! Alternatively, get in touch to learn more about the presentation.

To register for the next event, visit https://yachtracingforum.com/.